Crude Palm Oil (CPO) is mainly further processed into edible oil for food purpose. To meet the international industry’s standards for edible oil, the crude palm oil produced by oil mills should be refined in palm oil refinery plant. Palm oil refinery process mainly includes palm oil degumming, palm oil deacidification, palm oil bleaching and palm oil deodorization.

Small Oil Refinery Plant

Large Edible Oil Refinery Plant

The refining process removes water, odouriferous matter, phosphatides, free fatty acids and other impurities including dirt and traces of metals from palm oil mill. After processed in palm oil refinery plant, the final oil product is a kind of premium edible oil of consistent quality which not only satisfies customer requirements and industry’s standards in respect of Iodine Value, FFA, flavor, color, melting point, peroxide value, impurities and moisture.

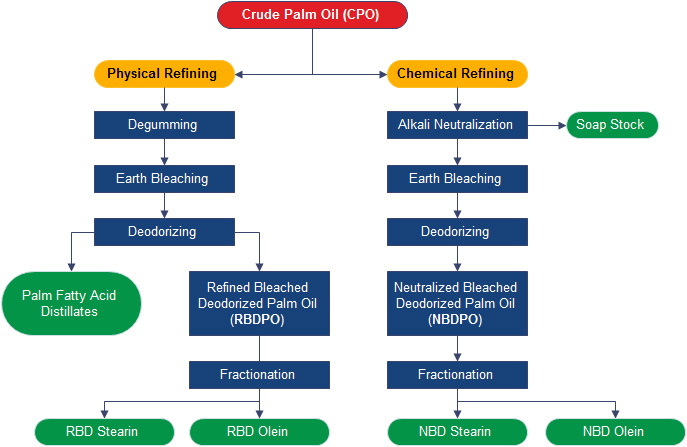

Crude palm oil can be processed by either physical refining (distillative neutralization, steam stripping) or chemical refining (alkaline refining) to produce RBDPO and NBDPO. RBDPO refers to refined, bleached and deodourised palm oil, while NBDPO refiers to neutralised, bleached and deodourised palm oil.

Curde Palm Oil Refining Process (Physical Vs Chemical)

Physical refining is also known as steam refining. In degumming process, it utilizes citric acid or food grade phosphoric acid to remove natural gums in the form of phosphatides. Then, in bleaching process, under vacuum, Fuller’s Earth is used to remove colouring matters and adsorb any metal ions. The deacidification and deodorization process is under high temperature and low pressure. By used of live steam, the FFA is stripped of. The steam is then recovered together with the entrained oil is as palm fatty acid distillate. The off-flavors and odours can also be removed from the crude palm oil in the steam distillation process. Before polishing, the refined oil needs to be cooled to 55°C.

Physical refining is also known as steam refining. In degumming process, it utilizes citric acid or food grade phosphoric acid to remove natural gums in the form of phosphatides. Then, in bleaching process, under vacuum, Fuller’s Earth is used to remove colouring matters and adsorb any metal ions. The deacidification and deodorization process is under high temperature and low pressure. By used of live steam, the FFA is stripped of. The steam is then recovered together with the entrained oil is as palm fatty acid distillate. The off-flavors and odours can also be removed from the crude palm oil in the steam distillation process. Before polishing, the refined oil needs to be cooled to 55°C.

Physical palm oil refinery plant is featured of high efficiency, simple production process and low effluent load.

In the chemical refining process, the FFA is removed by neutralisation with caustic soda (sodium hydroxide). This chemical reaction produces neutralised CPO and a soap stock. By used of a high-speed separator, the soap stock can be separated from the oil. Then, through earth bleaching, colour pigments and metal ions are removed from the neutralised oil. Then, in deodorization process, odoriferous matters such as ketones and aldehydes are removed by steam distillation under vacuum.

When refining crude palm oil with high carotene content, high initial FFA (up to 5%) and low phosphatides, chemical palm oil refinery plant is suggested, considering operating costs and refining losses.