Is the residual oil rate of the screw press related to the thickness of the oil cake?

What is the residual oil rate of the screw press?

Does it have anything to do with the thickness of the oil cake?

The oil output rate of the screw press does not only refer to a kind of oil crop, but is targeted according to specific conditions. Take peanuts for example, the oil output rate of peanuts is between 42% and 47%, but This is just a theoretical summary. What is the oil extraction rate of peanuts? We cannot generalize in terms of peanut varieties, planting, seeding, and storage. With these understandings, it is necessary to increase the oil yield of peanuts. What can be done to make the peanuts squeeze clean, produce good oil, and increase the oil yield? Let the technicians briefly introduce these issues for you:

1: Peanut raw materials should be dried and selected. Peanuts should be dried and cleaned before pressing. Many users ignore this pretreatment process. Unselected peanut raw materials will not only greatly reduce the oil yield, but also accelerate the wear of the oil press. Generally speaking, peanuts are equipped with a peanut peeling machine and a vibrating screening machine.

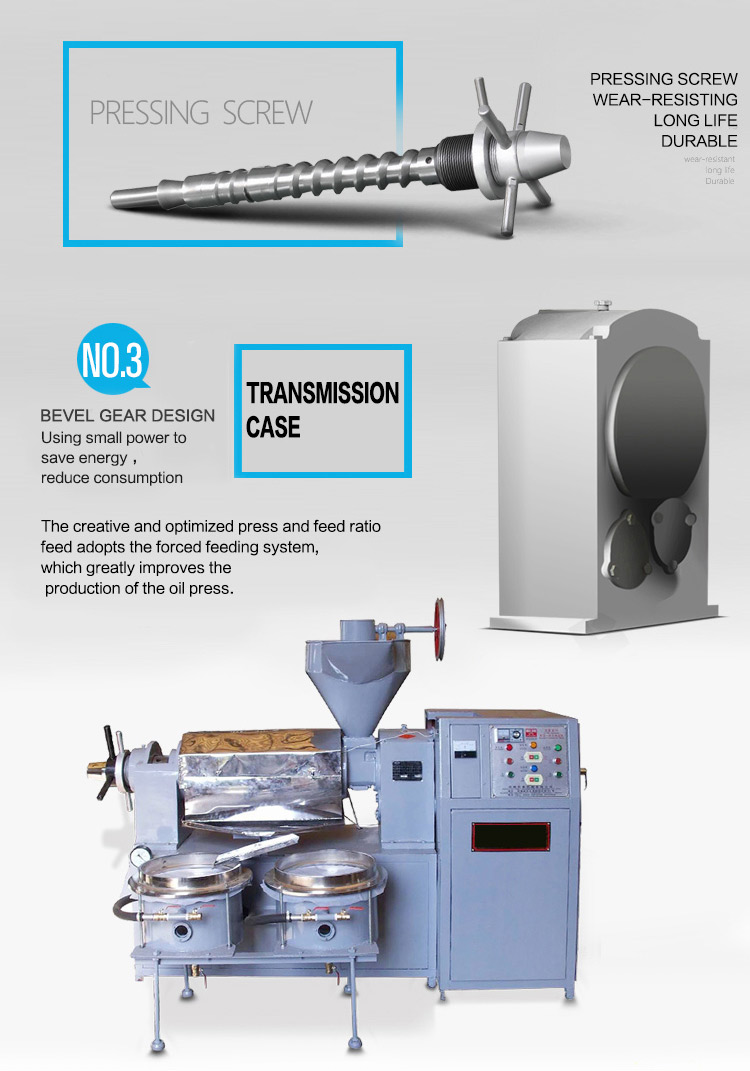

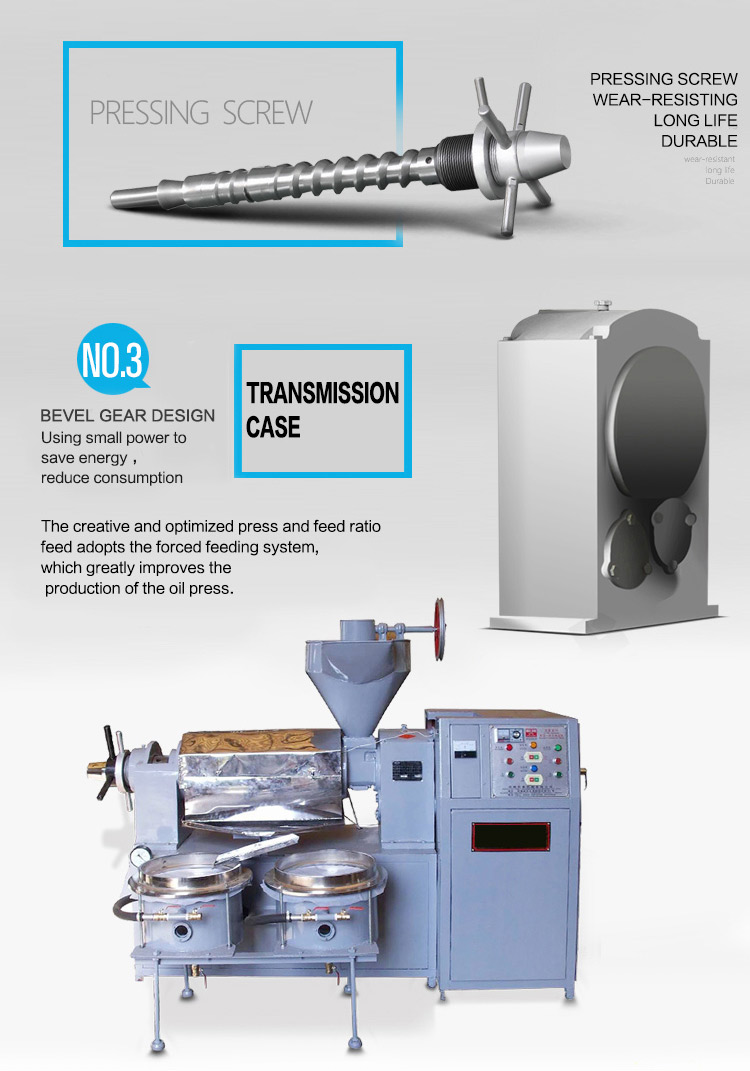

2: The quality of the peanut oil press also has an important influence on the oil yield of peanuts. From the perspective of the oil press equipment itself, it mainly depends on the pressure of the squeezer and the temperature of the snails. The oil press produced by our company uses a three-stage press. The oil extraction process can be divided into three stages, namely the feed (pre-pressing) section, the main pressing section (oil-out section), and the cake-forming section (heavy pressure oil part). During the squeezing process, a large amount of oil is squeezed out in the first half of the press chamber, that is, in the area of the feed section and the main pressing section.

3: The residual oil rate in the cake is too high. If the cake is too thick and the oil content in the cake is too high, it will directly reduce the oil yield of peanuts. How to control the residual oil rate and the thickness of the cake has become a concern of many processing households. We recommend customers to control the cake thickness between 0.8-2mm, and control the residual oil rate below 7%.

A good oil press can save users a lot of trouble in oil processing. The selected model can process oilseeds such as rapeseed, soybean, peanut, cottonseed, tea seed, etc. When buying the machine, first check whether the machine's exterior paint is even, check whether the machine parts are missing, and then turn the large pulley by hand to make it rotate a few more times to check whether there is any foreign matter such as iron in the press chamber, and whether it is stuck. At the same time, pay attention to whether the gear meshing in the gear box is normal.

The oil output rate of the screw press does not only refer to a kind of oil crop, but is targeted according to specific conditions. Take peanuts for example, the oil output rate of peanuts is between 42% and 47%, but This is just a theoretical summary. What is the oil extraction rate of peanuts? We cannot generalize in terms of peanut varieties, planting, seeding, and storage. With these understandings, it is necessary to increase the oil yield of peanuts. What can be done to make the peanuts squeeze clean, produce good oil, and increase the oil yield? Let the technicians briefly introduce these issues for you:

1: Peanut raw materials should be dried and selected. Peanuts should be dried and cleaned before pressing. Many users ignore this pretreatment process. Unselected peanut raw materials will not only greatly reduce the oil yield, but also accelerate the wear of the oil press. Generally speaking, peanuts are equipped with a peanut peeling machine and a vibrating screening machine.

2: The quality of the peanut oil press also has an important influence on the oil yield of peanuts. From the perspective of the oil press equipment itself, it mainly depends on the pressure of the squeezer and the temperature of the snails. The oil press produced by our company uses a three-stage press. The oil extraction process can be divided into three stages, namely the feed (pre-pressing) section, the main pressing section (oil-out section), and the cake-forming section (heavy pressure oil part). During the squeezing process, a large amount of oil is squeezed out in the first half of the press chamber, that is, in the area of the feed section and the main pressing section.

3: The residual oil rate in the cake is too high. If the cake is too thick and the oil content in the cake is too high, it will directly reduce the oil yield of peanuts. How to control the residual oil rate and the thickness of the cake has become a concern of many processing households. We recommend customers to control the cake thickness between 0.8-2mm, and control the residual oil rate below 7%.

A good oil press can save users a lot of trouble in oil processing. The selected model can process oilseeds such as rapeseed, soybean, peanut, cottonseed, tea seed, etc. When buying the machine, first check whether the machine's exterior paint is even, check whether the machine parts are missing, and then turn the large pulley by hand to make it rotate a few more times to check whether there is any foreign matter such as iron in the press chamber, and whether it is stuck. At the same time, pay attention to whether the gear meshing in the gear box is normal.