Processed palm oil is used for cooking. it is used in every American home for this purpose. Indonesia and Malaysia are the leading exporters of palm oil while India, China, United States, European Union and Pakistan are the primary importers of this product. It is also used as a major ingredient in processed food, detergent, soap and cosmetic. All you need is just the basic knowledge and training in palm oil processing technology which you can easily obtain by searching on the Internet and consulting a veteran in the field.

Making a good business strategy is the first step in starting a company or oil mill. Study the requirements of palm oil processing business in terms of technology, capital, market, and competition. Visit websites to get knowledge on the economic scope and statistics of the industry in your region. Study the operation of established industries to be aware of their working process.

Making a good business strategy is the first step in starting a company or oil mill. Study the requirements of palm oil processing business in terms of technology, capital, market, and competition. Visit websites to get knowledge on the economic scope and statistics of the industry in your region. Study the operation of established industries to be aware of their working process.

Make a strategy including a proposed location, target market, start-up capital, operational cost, and other finances. Obtain the necessary financing for your business,for instance, as of the year 2016 a palm oil processing machine which can process 400 to 500 pounds, costs around $70,000. Before choosing a location for your palm oil processing plant, you will need to consider the market, availability of the raw material and mode of transport. A good location will be very close to the target market and the source of raw material. For instance, a palm tree or kernel nut field so as to reduce the supply and transportation cost.

Our integrated palm oil extraction line is composed of all necessary machines for oil extraction which have solid and durable structures, fine properties and good adaptability. The plant is featured of safe, reasonable cost, excellent quality, high level of automation, continuous operation, and advanced technology.

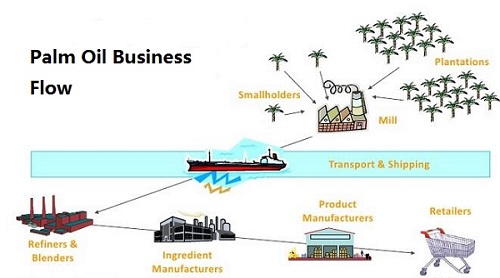

The global consumption of palm oil is rising, due to its low price and efficient commodity with many different uses. Palm oil extracting from fresh fruit bunches (FFB) is now the world’s most used vegetable oil, making the plantation of oil palm tree and the extraction of palm oil great investment projects. Below is one of the most common use process of palm oil processing.

1. Delivery of Fruit Bunches 2. Unloading Hoppers 3. Sterilizer Cage 4. Sterilizer 5. Stripper 6. Digester 7. Screw Palm Oil Press 8. Nut/Fiber Separator 9. Fiber Cyclone 10. Boiler 11. Nut Dryer 12. Nut Cracker 13. Shell Cyclone 14. Winnower 15. Palm Kernel Dryer 16. Vibrating Screen 17. Clarification Tank 18. Oil Purifier 19. Vacuum Dryer 20. Storage Oil Tank 21. Desander 22. Sand Trap 23. Decanter

A. Fresh Fruit Bunches B. Empty Bunchs C. Fruits D. Press Liquor E. Press Cake F. Nuts G. Fiber H. Boiler Fuel I. Dry Shell J. Dry Palm Kernel K. Coarse Solids L. Crude Palm Oil M. Top Oil N. Waste Water O. Dirt P. Oil Q. Clean Palm Oil R. Sand S. Desander Overflow T. Recovered U. Sludge V. Waste Water

Palm oil processing include bunches reception and threshing of the kernel nut, sterilization of the bunches, palm oil extraction and clarify of the oil, storage and recovery. As all of these processes require the use of machines, you will have to buy the good quality machines for each process.

A good quality palm oil processing machine will save you a lot of time and money in the long term. So it is necessary that you choose the machines carefully. For effective running of your palm oil processing plant, you will need to hire competent employees. Advertise vacancies for candidates experienced in the field of palm oil processing industry. You will need to hire a technician, an assistant, a storekeeper, from about 5 to 10 other staff members, a quality control official, sales, administrative and security officials.

Starting a palm oil business is a big achievement for any entrepreneur, but maintaining one is another issue. There are many challenges that face every entrepreneur when starting a palm oil mill. However, with determination and careful planning, you can overcome all of these problems.