How to control the residual oil rate and the thickness of the oil cake in the cake?

The oil yield of peanuts is between 45% and 50%. In recent years, more and more users have made profits by using

peanut oil presses to squeeze peanut oil. Recently, some customers reported that although the benefits of using peanuts to extract oil are objective, there are still some problems that worry users. For example, how to control the residual oil rate in the peanut oil press cake and control the thickness of the cake.

The customer’s concerns, we can understand that the residual oil rate in the oil cake after the peanut oil press presses peanut oil directly affects the oil output. Controlling the thickness of the oil cake is actually related to the oil yield. Today, I will help you explain how the peanut oil press controls the residual oil rate and the thickness of the oil cake.

The specific percentage of peanut oil output by using a peanut oil press is not fixed, and it cannot be generalized in terms of peanut variety, planting, seeding, and storage. In order to minimize the residual oil ratio in the oil cake, the following points should be paid attention to during the

oil extraction process.

①The peanut raw material needs to be processed carefully before it enters the peanut oil press. The oil quality is high and the oil yield is naturally high.

②The peanuts should be dried before being pressed and removed. Impurity removal includes plant branches and leaves, stones, silt and other impurities in peanut oil. Many users ignore this essential pretreatment process. As everyone knows, unselected peanut raw materials will not only greatly reduce the oil yield, but also accelerate the wear of the machine. Here we recommend special supporting equipment for peanut oil press: peanut sheller and vibrating cleaning screen.

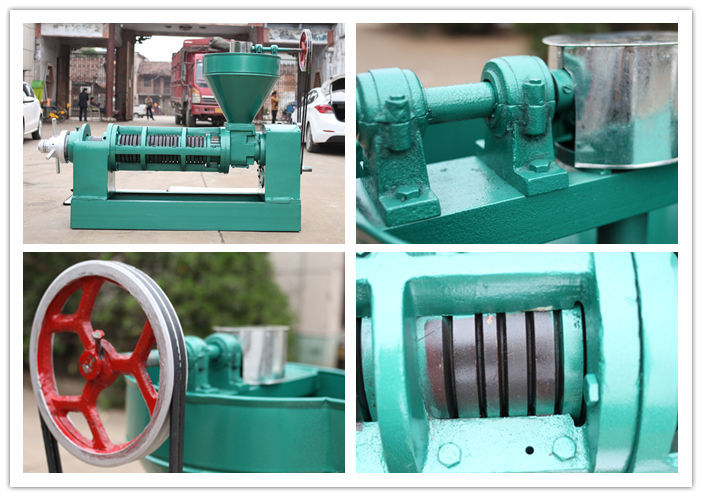

③The performance of the peanut oil press also has a vital influence on the peanut oil yield. From the perspective of the peanut oil press equipment itself, it mainly relies on the pressure of the squeezer and the temperature of the snail to squeeze the oil out of oil. The pressing grade of the peanut oil press and the thickness of the oil line directly affect the quality of the oil. The distribution of the high-pressure round row and the press chamber pressure directly affect the residual oil rate in the oil cake.

People who have been engaged in oil extraction for a long time know that if the oil cake is too thick and the oil content in the cake is too high, the oil yield of peanuts will be directly reduced during the pressing process. How to control the residual oil rate and the thickness of the cake when the peanut oil press is pressing peanut oil has become a concern of many processors. From the customer’s point of view, the oil press we produce is actively improving the research and development of new peanut oil presses. The peanut oil press we launched can not only control the cake thickness between 0.75-1.9mm, but also control the residual oil rate. Below 4%, it is a leader in the oil press industry.