General Analysis of Edible Oil Refining Technology

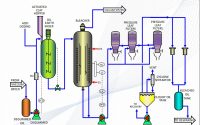

Edible oil refining processing line usually refers to refinery of crude oil. Presence of impurities in crude oil, not only affects the practical value and safe storage of oil, but also brings difficult to oil deep processing. However, edible oil refining machine is not a complete removal of impurities in oil, but remove detrimental impurities on consumption, storage, industrial production, such as gossypol, proteins, phospholipids, mucus, water, etc. removed and useful “impurities” such as vitamin E, sterols again reserved.Depending on the requirements and purposes of the unnecessary and harmful impurities are removed from the oil to obtain edible meet certain quality standards, that is the purpose of oil refining.Edible oil refining processing line introductionDepending on the operating characteristics and raw materials, oil refining processing line of choices can be broadly divided into three mechanical refining, chemical refining and physical refining processing lines.Sometimes one oil refining technology will produce another refining effect. For instance, edible oil alkaline refining (free fatty acid neutralization) is typically used chemical oil refining process. However, the reaction can be produced saponin pigment absorbing protein, mucus and proteins, and separated from the oil together. Alkaline oil refining is always accompanied by physical and chemical oil refining process.Oil refining is more complex and flexible in operation. Technical condition and economical profit must be taken into consideration during edible oil refining project. Only if a suitable oil refining processing line can obtain high quality and safe edible oil.