Edible oil Refining – Bleaching

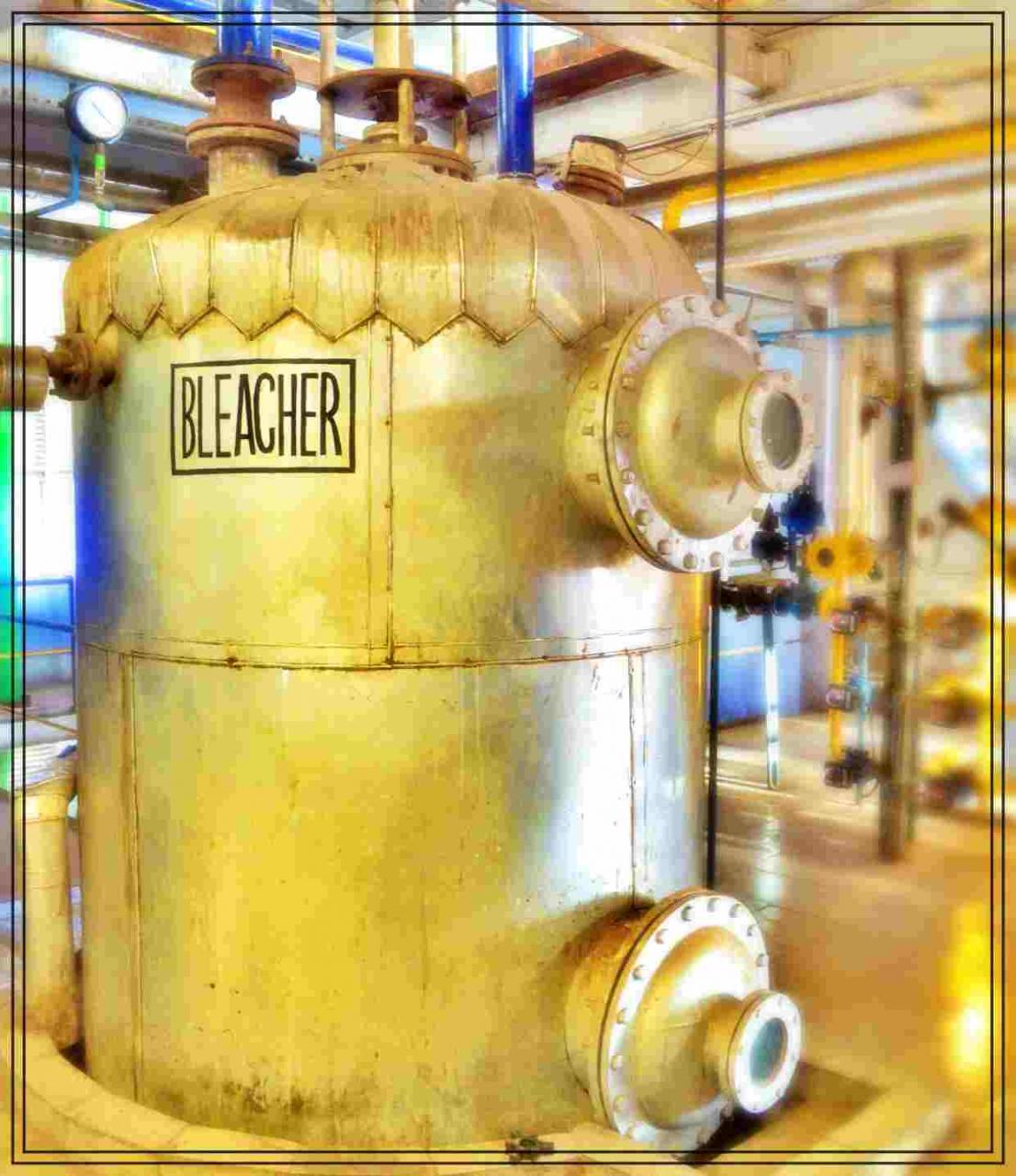

Bleaching Technology

In addition to color pigments, Bleaching also removes residual phosphatides, metal contaminants, soaps and oxidation products.

Oil undergoes Pre-treatment with Phosphoric acid/citric acid and the pre-treated oil is given a pre-determined retention before going to the Bleacher. This step splits soap and traps metal contaminants.

The pre-treated oil is mixed with bleaching earth in inline static mixer.

Bleacher is equipped with mechanical agitation and steam sparging for better contact between oil and bleaching earth. Bleacher is kept under vacuum of 710 mm Hg. A retention time of 40 – 60 minutes is given to slurry for efficient contact and adsorption of color pigments and other impurities on to the Bleaching earth.

The slurry is then sent to Pressure Leaf Filters for filtration of bleaching earth from oil, followed by polish filtration. The spent cake is then dried by steam blowing to remove oil from it.

Salient Features

Pretreatment of Oil to eliminate metal contaminants and residual P-contents

Slurry preparation & Bleaching in single reactor – Compact system

No carryover of bleaching chemical to Vacuum system

Wet Bleaching with effective mechanical agitation

Enhanced adsorption of coloring matters by bleaching earth

Lower consumption of Bleaching earth

Ensure accurate (Automated) dosing system of Bleaching earth

Lower consumption of utilities

Hi.

I have new BIG project, reorganization of Jojoba oil factory.

Now we need / searching for oil BLEACHING system ( Odor and color removal ).

Cosmetic industry

System for batch 5-10 ton per bath. Yearly 100 ton.

Happy new Year!!!